It’s the white plastic pipe commonly used for plumbing and drainage. PVC stands for polyvinyl chloride, and it’s become a common replacement for metal piping. PVC’s strength, durability, easy installation, and low cost have made it one of the most widely used plastics in the world. PVC is a thermoplastic material that is molded into different shapes to create pipes, fittings, valves and other liquid handling supplies.

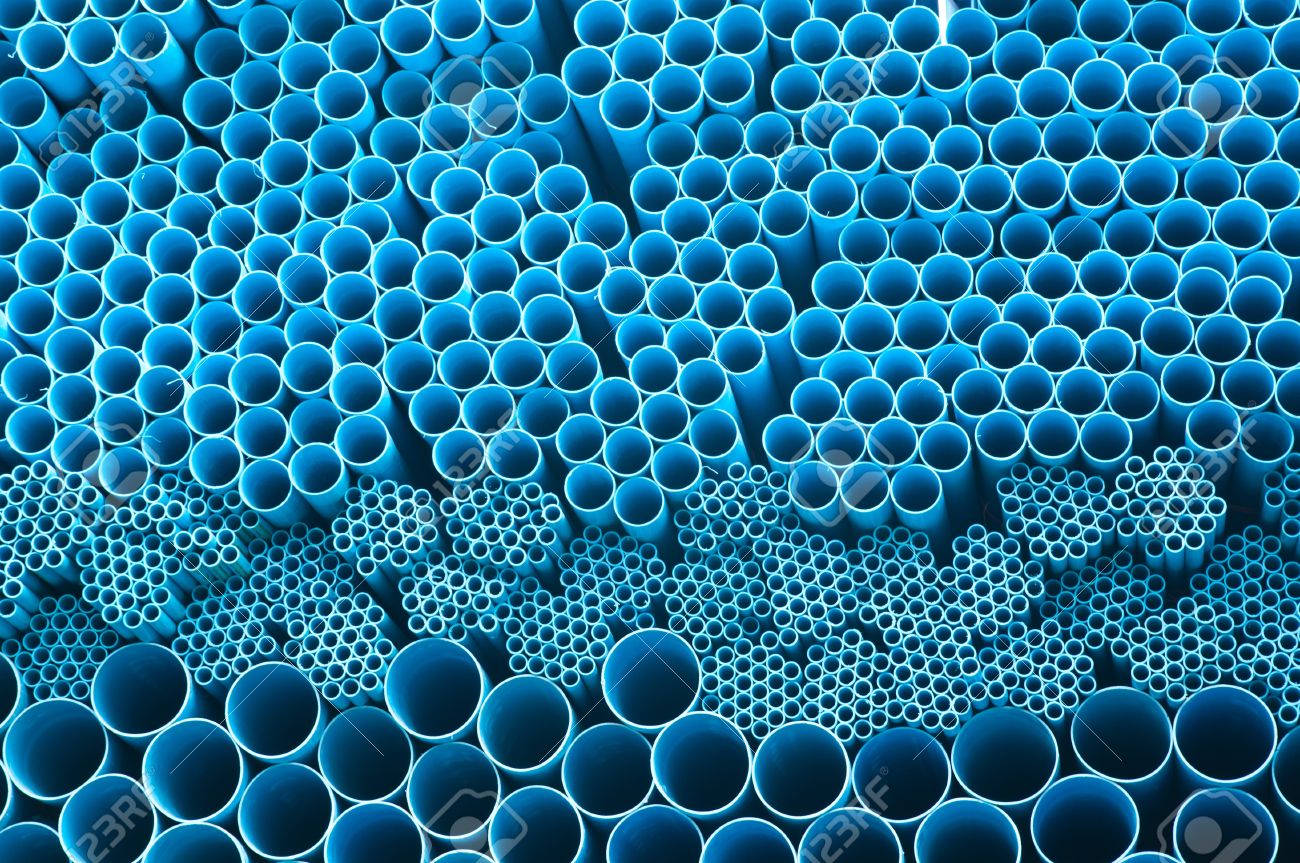

PVC pipes are extremely strong and most importantly, these pipes are 100% resistant to corrosion. While red is used for hot water, blue is used for cold water, but there’s no difference between the material.

There are many uses for PVC. As a rigid plastic, it is used as vinyl siding, magnetic stripe cards, window profile, pipe, plumbing and conduit fixtures. PVC is commonly used as the insulation on electric wires. Frequently in applications where smoke is a major hazard (notably in tunnels) PVC-free LSOH (low-smoke, zero-halogen) cable insulation is used.

PVC pipes are majorly used for manufacturing sewerage pipes and agricultural pipes. PVC pipes have been used for more than 60 years and show that they have very long-lasting material properties. They are easy to install, strong and durable and, when they eventually reach the end of their service life, they can be recycled back into new PVC pipes. As a result, PVC pipe systems are very cost efficient.

Some of the renowned manufacturer and supplier of PVC pipes are as follows:

- Astral Pipes

- Finolex

- Utkarsh India

How can the rigidity of the PVC Pipes be improved?

- Materials must be well plasticized,

- PVC Stabilizers used should be of high quality with good lubrication.

- The lead content of the PVC Stabilizers should be 28% or more, pHr should be around 2.4 to 2.8. Waldies owned Ducatus PVC One Stabilizers namely Ducatus 3248, Ducatus 3258 & Ducatus 7305 are the recommended stabilizers for usage.

- Reduce lubrication, instead, use PE Waxes with 3.0 pHr.

- The amount of Calcium Carbonate be under 50%. The volume should be above 2.7 mesh above 1000.

- After die processing, draw from two directions – longitudinally and axially.

- Use lubrication which has macro-molecular structure.

Image credit: https://www.123rf.com/photo_15665409_blue-pvc-pipe.html

We are using 3278 one pack. we want to know about other products of your company for PVC conduit pipe mfg