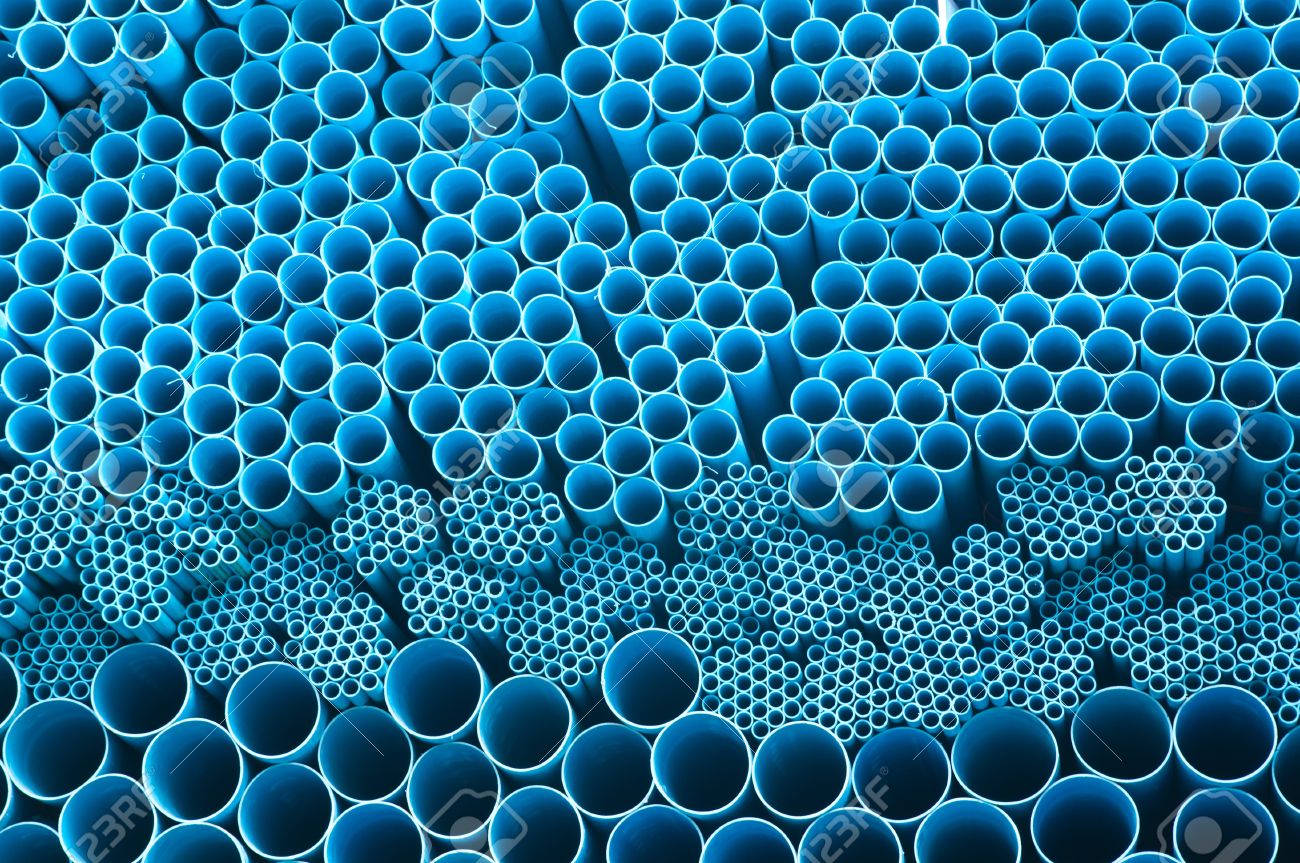

Waldies unveils new manufacturing site, eco-friendly PVC Stabilizers at Plast India 2023

February 3, 2023, New Delhi, India: Waldies has unveiled eco-friendly PVC Stabilizers for the industry at the PlastIndia International Exhibition 2023. The 1858-origin company, also announced new manufacturing site at Dausa, Rajasthan. Waldies, a renowned manufacturer of PVC Stabilizers in Asia unveiled high performance PVC Stabilizers conforming to international regulations. The organization, that has over […]